In recent years, the

plastic mold industry has developed rapidly in our country, followed by increasingly fierce market competition. After joining the WTO, foreign mold manufacturers entering the domestic market must stand out from the fierce competition, develop mold standard parts, and implement molds. Specialized production is essential.

As one of the pillar industries of my country's light industry, the plastic industry has maintained a growth rate of more than 10% in recent years. In the plastic industry, the plastic hardware industry market is very active, becoming a new consumption hotspot and a new economic growth point. The market prospects of plastic hardware molds are considerable, but compared with foreign technology, it is far behind.

At present, my country's mold needs to break through the bottleneck restricting the development of the mold industry. Because with the rapid development of China's pillar industries such as machinery, automobiles, home appliances and building materials, plastic molds account for about 30% of the entire mold industry. However, due to the complex shape of plastic mold parts, there are higher requirements for its design level. Therefore, the technical level such as mold trial results inspection must be innovative to keep up with the development trend of the times, otherwise the development of plastic molds will be restricted.

The industry believes that mold manufacturers must improve their own technology if they want to break through the bottleneck. At the State Council meeting on the 26th, the Premier also stated that today's technological revolution plays an extremely critical role in economic development and promotion of economic upgrading. Advocating mass entrepreneurship and innovation also uses innovative means to promote entrepreneurship.

The mold foreign trade deficit is increasing year by year

Although the growth rate of mold exports has been greater than that of imports in recent years, the absolute amount of increase is still that imports are greater than exports, which has caused the mold foreign trade deficit to increase year by year. This situation has improved in 2006, and the deficit has decreased slightly. There are two main reasons for the increase in the foreign trade deficit of molds: First, the continuous rapid development of the national economy, especially the rapid development of the automobile industry, has brought strong demand for molds. Some high-end molds cannot be produced in China, so they have to be imported; but there are some. Molds can be produced domestically and are also imported. This is related to China's current tariff policy and project approval system. The second is insufficient encouragement for mold exports. Now molds, like other mechanical and electrical products, have an export tax rebate rate of only 13%, but not 17%.

According to the forecast report on the development prospects of China's plastic mold industry, plastic mold manufacturers should focus on the development of large, precise, complex, and long-life molds with high technology content, and vigorously develop the international market and develop export molds. With the rapid development of China's plastics industry, especially engineering plastics, it is foreseeable that the development speed of China's plastic mold industry will continue to be higher than the overall development speed of the mold industry, and the annual growth rate will remain at about 20% in the next few years.

In the four elements of mold quality, delivery cycle, price, and service, more and more users have put delivery cycle first. It has become a trend to require mold companies to deliver as soon as possible. Companies do everything possible to improve their adaptability, technical standards, equipment, management and efficiency are all effective means to shorten the mold production cycle.

Vigorously improve the development ability, push the development work forward as much as possible, until it is involved in the product development of mold users, and even develop before there is no clear user target, turning passive to active. At present, TV and monitor shells, air conditioner shells, and motorcycle plastic parts have adopted this method, and the development of mobile phone and telephone molds has also begun to try. This approach broke the long-standing passive situation that mold factories can only wait for contracts to design molds according to user requirements.

With the improvement of the design and processing level of mold companies, mold manufacturing is changing from relying mainly on the skills of fitters to relying mainly on technology. This is not only a change in the means of production, but also a change in the mode of production and a rise in concepts. This trend has led to the continuous improvement of the standardization of molds, higher and higher mold accuracy, shorter and shorter production cycles, and lower and lower ratios of fitters, which ultimately promoted the continuous improvement of the overall level of the mold industry. China's mold industry currently has more than 10 national high-tech enterprises and about 200 provincial and municipal high-tech enterprises. In line with this trend, it is an inevitable requirement that the main backbone of the production of molds gradually transform from technical talents to technical talents. Of course, at present and for a long time, skilled talents are still very important, because after all, it is difficult for molds to completely get rid of the dependence on skills.

Mould enterprises and their mould production are rapidly developing towards informatization. In the information society, as a high-level modern mold company, the application of CAD/CAM is far from enough. At present, many companies have adopted technologies such as CAE, CAT, PDM, CAPP, KBE, KBS, RE, CIMS, ERP and other advanced manufacturing technologies and virtual network technologies, which are all manifestations of informationization. This trend towards informatization has become the consensus of the industry.

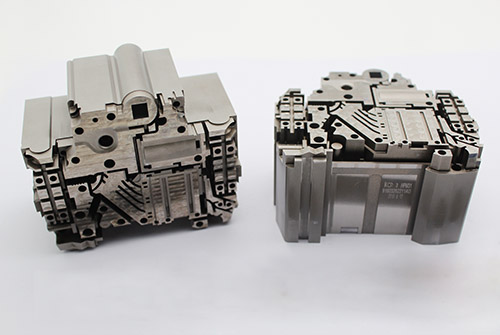

Dongguan Sen Entropy Precision Mould Co., Ltd. is mainly engaged in the development of precision moulds and the processing of mould parts. Focus on the development, production and sales of mobile phone connector plastic molds, automotive connectors, relays, photoelectric molds, mobile phone lens molds and spare parts.

skype

skype