PRODUCT

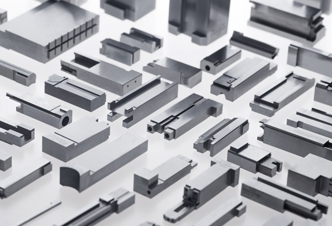

- 01PLASTIC MOLD PARTSPLASTIC MOLD PARTS

- 02STAMPING DIE PARTSSTAMPING DIE PARTS

- 03PLASTIC MOLDPLASTIC MOLD

Covers stamping die punches, stamping die punches, stamping die guide bushings, etc....

Enter the topic

Covers mobile phone shell plastic molds, plastic molds, switch panel plastic molds, etc...

Enter the topic

Covers high quality precision mold parts, precision mold parts processing, precision mold parts processing, etc...

Enter the topic

Dongguan Sen En En Precision Mould Co., Ltd. is mainly engaged in the development of precision molds and mold parts processing enterprises. Focus on the development, production and sales of mobile phone connector plastic molds.......[Details]

Products are widely used in four major product areas, serving the country's high-end mold customers, providing customers with world-class mold solutions, they witness our growth [Details]

Founded in 1945, Yishengbai sells high quality Swedish mold steel to the market. Yishengbai is headquartered in......

Datong Special Steel Co., Ltd. was founded in 1916. In 1950, Datong Special Steel Co., Ltd. was established. It is headquartered in Nagoya,......

The Kyocera Group's global business involves raw materials, parts, equipment, machines, services, and networks. Within the group......

Hongfa shares (stock code: SH600885) was established in 1984. For more than 30 years, it has been adhering to the enterprise spirit of “continuous......

There are 3 types of wire cutting, and the accuracy of different types are also different: fast wire, medium wire and slow wire; generally fast wire can reach +/- 0.02mm, surface roughness can reach Ra3.2 The precision of the middle wire can reach +-/0.01mm, the surface roughness can reach ≤Ra3.2; the accuracy of slow wire can reach +/-0.005mm, and the surface roughness can reach Ra0.8

Fine-finishing grinding precision can reach IT5~01, and the appearance roughness can reach 0.63~0.01 microns. Fine-form grinding can be used to machine a variety of appearances of metal and non-metal materials, such as flat, cylindrical, conical, threaded, toothed, spherical, and the like. Manually grind in single-piece and small-batch production, and mechanically grind in large batches.

Protecting the integrity of the cavity surface is one of the most critical issues in EDM processing. The integrity of the surface finish of the cavity depends on the change in the heat transfer of the cavity in the EDM process, including the transfer of control charge between the electrode and the workpiece. During the electrical discharge machining process, the current applied to the workpiece will melt and vaporize the metal of the workpiece, forming a thermal deformation layer on the cavity.

①The accuracy and surface roughness of the workpiece to be machined should be guaranteed.

②The processing route is the shortest, the idle travel time is reduced, and the processing efficiency is improved.

③Simplify the workload of numerical calculations and simplify the machining process

④For some reusable programs, subroutines should be used

In recent years, the development of the plastic products industry has been smooth, and it has also been developed using new materials such as plastic steel and rubber. Its finished products are used in many industries. And because plastic p... [More]

What are the processing requirements for precision parts? Precision stamping die parts For precision parts, the processing is very strict, and the processing procedures include cutting in and out. There are specific requirements for size an...

Stamping die is the main process equipment for stamping, and it is a key tool in industrial production. There are many factors affecting the service life of stamping dies. The failure of stamping dies is one. The main forms are wear failure,...