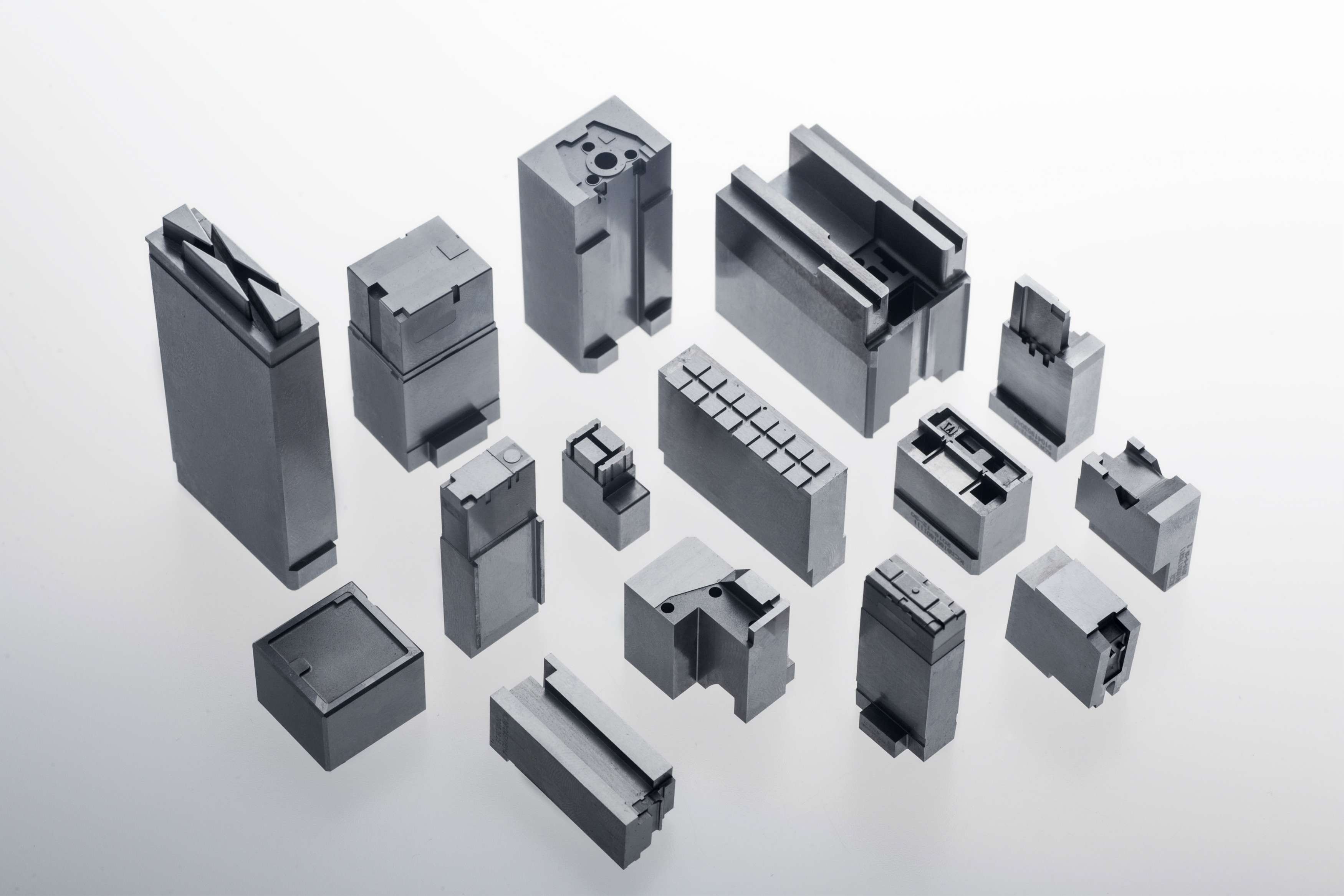

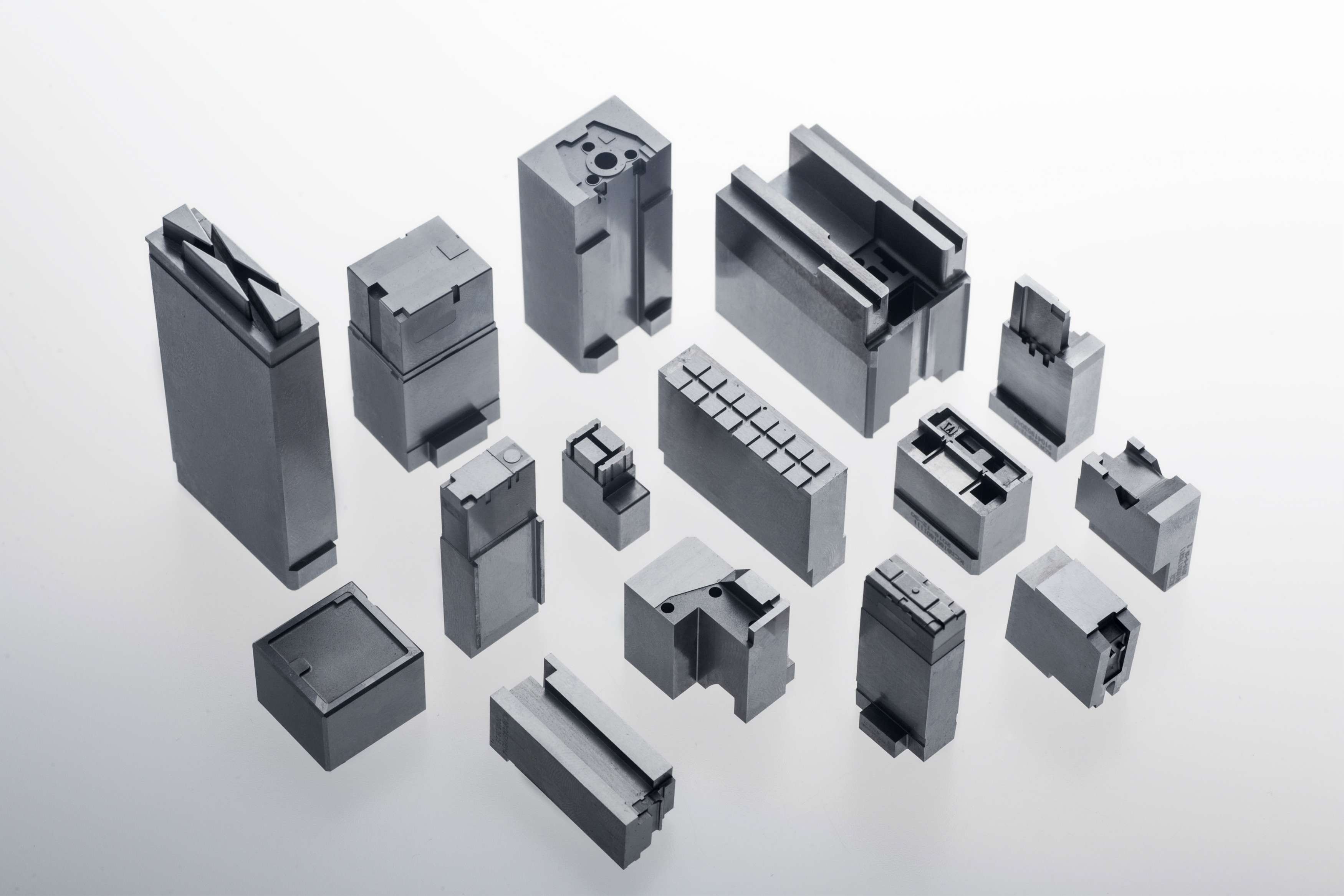

The plastic mold consists of two parts: a movable mold and a fixed mold. The movable mold is mounted on the moving template of the injection molding machine, and the fixed mold is mounted on the fixed template of the injection molding machine. In the injection molding, the movable mold and the fixed mold close constitute a casting system and a cavity, and when the mold is opened, the movable mold and the fixed mold are separated to take out the plastic product.

The six major systems of plastic molds are: pouring system, temperature control system, forming part system, exhaust system, guiding system, and ejection system. The gating system and the molded part are in direct contact with the plastic and vary with the plastic and the product. It is the most complicated and most varied part of the mold, and requires the highest degree of smoothness and precision.

First, the pouring system

The plastic mold pouring system refers to the flow path part of the plastic before entering the cavity from the nozzle, including the main channel, the cold material hole, the split channel and the gate.

Second, the temperature control system

In order to meet the mold temperature requirements of the injection process, a temperature adjustment system is required to adjust the temperature of the mold. For injection molds for thermoplastics, the cooling system is primarily designed to cool the mold (the mold can also be heated).

Third, the molding parts system

The plastic mold forming part system refers to various parts and components constituting the shape of the product, including a movable mold, a fixed mold and a cavity (a concave mold), a core (a punch), a forming rod and the like. The core forms the inner surface of the article and the cavity (female) forms the outer surface shape of the article. After clamping, the core and cavity form the cavity of the mold.

Fourth, the exhaust system

The plastic mold exhaust system is set up to remove the gas generated by the melting of the air and plastic in the cavity during the injection molding process, and the gas surface is formed on the surface of the product when the exhaust gas is not smooth. The exhaust system of the plastic mold is usually a slot-shaped air outlet opened in the mold to discharge the gas of the original cavity air and the molten material.

Five, guiding system

The plastic mold guiding system is to ensure that the moving mold and the fixed mold can be accurately centered during mold clamping, and the guiding member must be provided in the mold. In the injection mold, four sets of guide columns and guide sleeves are usually used to form the guide members, and sometimes the inner and outer tapered surfaces are respectively arranged on the movable mold and the fixed mold to assist the positioning.

Six, the ejection system

The plastic mold ejection system generally comprises: a thimble, a front and rear ejector plate, a thimble guide rod, a thimble return spring, a thimble plate locking screw and the like. When the product is molded and cooled in the mold, the front and back molds of the mold are separated and opened, and the plastic product and its aggregate in the flow passage are pushed out or pulled out of the mold opening and flow path position by the pushing mechanism-the ejector pin under the push rod of the injection molding machine. In order to carry out the next injection molding work cycle.

skype

skype