First, the common problems of precision plastic mold processing:

1, size, plastic materials have shrinkage, mold size should be multiplied by material shrinkage

2. The runner design should be reasonably balanced, and the exhaust should be done well.

3, the flying model is not good, the product will have a cloak

4, demoulding ejection, cavity drafting is sufficient, surface polishing is good, thimble arrangement should be reasonable, oblique top row travel enough

5. Whether the cooling water channel can quickly balance the cooling mold

6, the size of the rubber inlet is appropriate, too large will make the product separation difficult, too small plastic parts are not full

7. Do not install the wrong parts in the assembly mold, and the movement between the modules should be smooth.

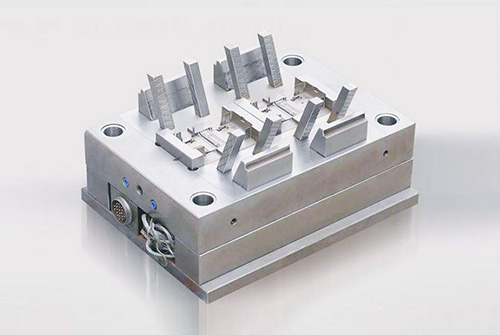

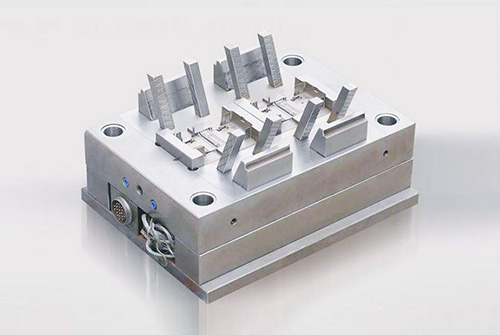

Second, the process of precision plastic mold processing

1. Cutting material. Front mold material, back mold material, insert material, row material, inclined top material

2, open the box. Front mold frame

3, open rough. The front mold cavity is thick, the rear mold cavity is thick, and the parting line is thick.

4, copper public. Front mold copper male, rear mold copper male, split mold line Qing angle copper public

5, wire cutting. Insert parting line, copper male, slanted top pillow

6, computer 锣. Fine split mold line, fine mold core

7, electric sparks. Front mold rough, copper male, male mold line clear angle, rear mold bone position, pillow position

8, drilling, pinhole, thimble

9, row position, row position

10, inclined top, thimble, with thimble

11, other. (1) code die pit, garbage nail (limit nail); (2) flying die; (3) nozzle, support head, spring, water transport; (4) provincial mold, polishing, front mold, rear mold bone position; (4) Fine water structure, drawbar screw hook, spring quenching, nitriding of the surface of the row; (5) repair lettering.

skype

skype